Operations and Development Projects

OVERVIEW

KPO is the Operator of the Karachaganak oil and gas condensate field (KOGCF) is located in north-west Qazaqstan and covers an area of over 280 km2. Karachaganak is a unique field with complex operating conditions also due to extreme continental climate. The field is some 1,600 m thick and very complex and unique with its top at a depth of around 3,500 m. The extracted hydrocarbons contain up to 4.5 % of highly toxic and corrosive hydrogen sulphide (H2S), as well as carbon dioxide (CO2) which can be highly corrosive in certain conditions.

According to the latest Reserves Re-Determination Report for the Karachaganak field (accepted by the RoQ State Reserves Committee (GKZ) on 17.11.2017), it is estimated that the Karachaganak Field contains some 13.6 billion barrels of liquids and 59.4 trillion cubic feet of gas, of which approximately 14.2 % of liquids and 13.5 % of gas have been recovered as of 2021.

The Company annually invests the funds in the application of leading-edge technologies to maximize sustainable economic value and minimise environmental impact. The total investment in the development of the Karachaganak oil & gas condensate field since the signing of the FPSA in 1997 to 31.12.2021 has totalled over USD 28.4 bln. As of end 2020, 4,076 people worked in the KPO organisation.

KPO FACILITIES

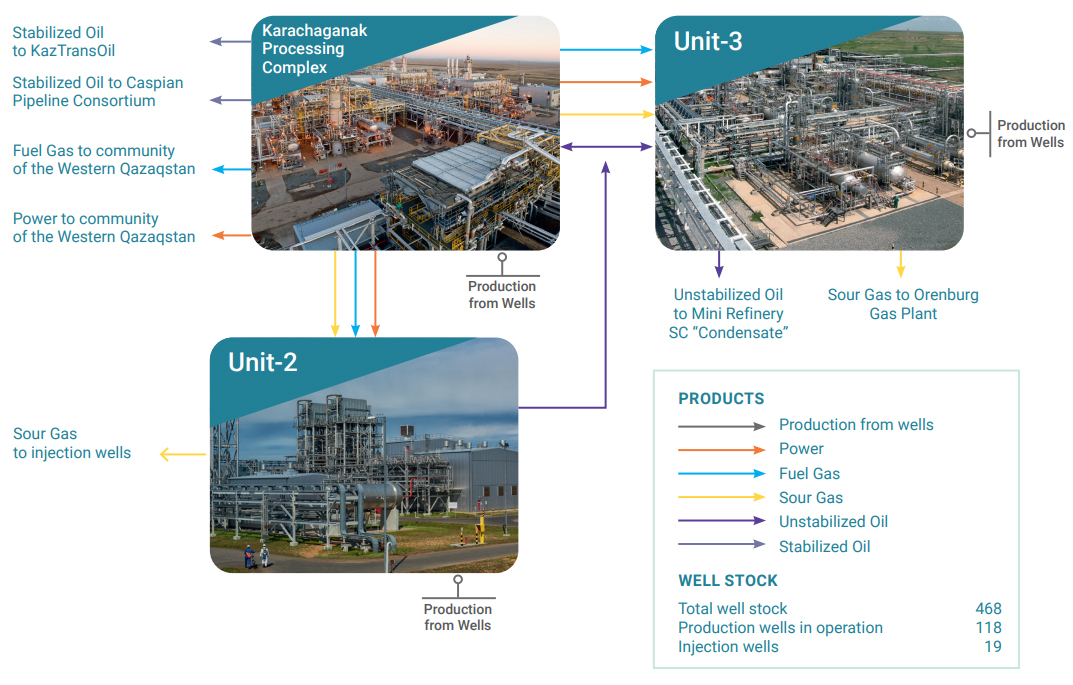

Hydrocarbon production and processing occurs at the three major interconnected units: the Karachaganak Processing Complex (KPC), Unit 2 and Unit 3. Approximately 2,000 kilometres of pipelines make up the infield system linking the major facilities and allowing efficient flows of production from the wells and among the units. Amongst the facilities, there is an Early Oil Production Satellite (EOPS) and Eco Centre. An overall view of the facilities is graphically presented on the Figure 4.

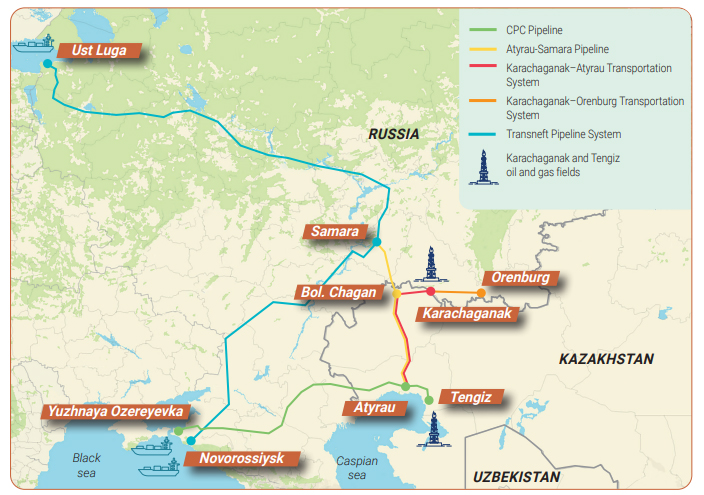

The transportation system operated by KPO includes the main export route for stabilised liquid hydrocarbons – Karachaganak – Atyrau Transportation System (KATS) with two pumping stations: one at KPC and the other at Bolshoi Chagan, and a receiving and storage facility in KPO Terminal in Atyrau. The other export route is the Karachaganak – Orenburg Transportation System (KOTS), which is used by KPO for transporting gas to Orenburg Gas Plant in the Russian Federation.

In the first half of 2021, the COVID-19 pandemic has still affected our activities. Drilling was resumed in September 2021.

As of end 2021, 118 producing and 19 re-injection wells were online at Karachaganak, from a total well stock of 468 wells. In 2021, KPO well stock was increased by one new horizontal well compared to the previous year: 468 wells in 2021 versus 467 wells in 2020. One more well has been started in 2021 and ongoing through 2022; two wells were worked over.

Fig. 4. Karachaganak facilities and products (as of end 2021)

OUR PRODUCTS AND EXPORT ROUTES

KPO extracts and processes stabilised and unstabilised liquid hydrocarbons, raw gas and fuel gas. The majority of hydrocarbons produced in the Karachaganak Field are exported to maximize net sales revenues.

In 2021, around 99.98 % of liquid production was sold as stabilised oil to the Western markets via the following routes:

- the Caspian Pipeline Consortium (CPC) pipeline,

- the Atyrau – Samara pipeline and further through the Transneft system.

The CPC pipeline delivers KPO oil to the Black Sea port of Novorossiysk (Yuzhnaya Ozereyevka), whereas the Atyrau-Samara pipeline is used to deliver oil to the Ust-Luga port in the Baltic Sea (see Fig. 5). The key marketing objective is to maximize oil export via CPC pipeline, which is the main export route with the highest netback cost. The Atyrau-Samara route is used as an insurance backup in case of disruptions of the export through CPC.

In 2021, KPO exported total of 10.34 mln tonnes of stabilised oil, out of which 10.25 mln tonnes were delivered through CPC. To maximize revenue, nearly 0.085 mln tonnes of oil were exported via the Atyrau-Samara pipeline. As part of maintenance at the Karachaganak Processing Complex during the reboilers’ washing, liquids were delivered to Condensate SC`s refinery.

Fig. 5. KPO export routes

The gas produced from the Karachaganak Field is:

- re-injected into the reservoir to maintain reservoir pressure,

- sold as raw gas to KazRosGas LLP under the long-term Gas Sales Agreement,

- sweetened (i.e. cleared from H2S) to generate electricity for KPO facilities including Gas Turbine Power Plant and for local power distribution companies.

In 2021, KPO sold 8.2 bln m3 of raw gas to KazRosGaz for processing at the Orenburg Gas Plant.

OPERATIONS AND SALES IN 2021

In 2021, KPO produced 134.1 mln barrels of oil equivalent (BOE) in the form of stable and unstable liquids and gas. Gas production in 2021 reached 19 mln m3. To maintain reservoir pressure, KPO re-injected ~ 10 bln m3 of gas into the reservoir, a volume equivalent to about 52.7 % of the total gas extracted.

Tab. 1. Production in 2021

|

|

|

2021 |

2020 |

2019* |

|

Total Production |

Mboe |

134.1 |

143.9 |

137.9 |

|

Total equivalent stable oil |

Kt |

10,338 |

10,941 |

10,147 |

|

Total gas production |

Mscm |

18,980 |

20,214 |

18,614 |

|

Gas Injection into a reservoir |

Mscm |

9,998 |

10,362 |

8,710 |

|

Sweet Gas for internal needs |

Mscm |

789 |

761 |

685.4 |

* Full turnaround year

Tab. 2. Sales in 2021

|

|

|

2021 |

2020 |

2019 |

|

Total Sales |

Mboe |

130.7 |

139.4 |

134.7 |

|

Stable Liquids |

kt |

10,366 |

10,857 |

10,160 |

|

Unstable Liquids |

kt |

1.5 |

24 |

9.9 |

|

Raw Gas |

Mscm |

8,182 |

8,986 |

9,113 |

|

Sweet Gas to the West Qazaqstan Oblast to generate electricity for community |

Mscm |

70 |

90 |

89 |

POWER GENERATION

For production needs within the Karachaganak field, KPO generates electrical power at its own Gas Turbine Power Plant (further as GTPP). Generated power is transmitted to the own production units throughout the Field, which include Karachaganak Processing Complex, Unit-2, Unit-3, Gathering system, Eco Centre, Pilot Camp, IT&T Data Centre in Aksai and the Karachaganak – Atyrau transportation system covering the oil pumping station in Bolshoi Chagan and block valve stations 1-26.

Four turbines, three of which are dual-fueled, are installed and operating at the KPO Gas Turbine Power Plant. In addition, KPO supplies electricity for the needs of the Western Qazaqstan Oblast communities with capacity of circa 25 MW in winter and circa 20 MW in summer.

In 2021, at the GTPP minor inspection of gas turbine generators (GTG) #1 and #2 was completed, as well as the overhaul of GTG #3. The overhaul of GTG #4 has lasted from October 2020 to May 2021 due to extra scope of dismantling of the old stator rewinding because of the insulation damage defect identified in the course of the routine inspection. Manufacture, delivery and installation of the new stator winding were carried out at the GTPP without removing the generator to the producer. The activities took longer than expected also due to the COVID impact and delays in spare parts delivery.

Besides, in 2021, the inspection of the hot-gas-path of turbines ##1, 2 and 3 was carried out, as well as the overhaul of turbine #4. During the year, the work was carried out to implement the option of energizing a block transformer from the generator itself on three turbines, which allowed reducing the number of switches and the associated risks when restarting the turbines after repairs.

Power export to West Qazaqstan Oblast

As part of the Karachaganak Field’s Final Production Sharing Agreement (Art.I, Section 1.1.), KPO generates and exports power to the West Qazaqstan Oblast.

KPO exports power to electricity suppliers, such as AksaiEnergo LLP and Batys EnergoResursy LLP, who in their turn supply the power to the communities and other end consumers in West Qazaqstan Oblast.

Throughout 2021, KPO exported power from 20 to 34 MW to the regional grid, while the total volume of power export to WQO equalled ~ 225.6 mln kW-h or about 35 % of the total volume of the regional energy consumption. Reduction of the power export in 2021 by some 20 % compared to 2020 was due to the unplanned overhaul of the Gas Turbine Generator #4, and the major routine maintenance of other three turbines. That had led to decline of total power generation at the KPO GTPP and, hence the decrease of power volumes available for the region. One more notable factor in the decline was the launch of a new section of the Karachaganak Gas Debottlenecking Project (KGDBN) at KPC, which has led to a gradual increase of KPO’s own energy consumption by 7-8 MW starting from the second quarter of 2021.

Supply of power and fuel gas in the period of 2019 – 2021 is shown in Table 3.

In 2021, KPO used mainly its own gas for power generation. Purchases of gas from the third-party supplier to generate power for the WQO needs made circa 6.5 % of the GTPP total gas consumption. Those purchases were made mostly during the unstable operation of the Fuel Gas Sweetening unit at KPC (5-339 area).

In May and October 2021, disturbances (alarm events) have occurred in the external electrical power networks of the West Qazaqstan Regional Electricity Company, leading to trivial losses in KPO’s production.

Tab. 3. Supply of power and fuel gas, 2019–2021

|

Description |

Unit of meas. |

2021 |

2020 |

2019 |

|

Electrical power exported to West Qazaqstan, including: |

mln kW-h |

225.56 |

296.93 |

330.26 |

|

to AksaiEnergo LLP |

mln kW-h |

26.28 |

26.35 |

26.28 |

|

to Batys EnergoResursy LLP |

mln kW-h |

199.28 |

270.58 |

303.98 |

|

Use of fuel gas to generate electrical power for West Qazaqstan, including: |

mln m3 |

75.88 |

99.35 |

112.06 |

|

Own gas sales |

mln m3 |

70.98 |

89.95 |

88.98 |

|

From third party supplier |

mln m3 |

4.90 |

9.40 |

23.08 |

TECHNOLOGIES IN DRILLING

In 2021, KPO continued building on the strong foundation laid in the past years, working on minimization of the impact from drilling and well services operations on the environment. As previously, we continued our journey towards zero emission and applied measures listed below to reduce greenhouse gas (GHG) emissions, and consumption of water and resources:

- Continued initiatives such as using wireline instead of coiled tubing for post stimulation.

- Milling of downhole hardware and high-efficient environmental friendly burners to eliminate where possible / reduce the need for flaring and the need for disposal of contaminated fluids.

- Restarting our drilling campaign, delivering wells that will allow increased oil production offsetting existing high gas producing (GOR) wells.

- High Rate Well Test setup with High Pressure Separators combined with multiphase high rate flow pumps (High Gas Volume Fraction Pumps – HGVF) to enable 'zero' flaring well test / clean-up activity on new wells. Successfully implemented on 4 wells in 2020 / 2021 with ~24 Kt of CO2-eq emission reduction and ~53Kbbl of additional liquid production achieved per well.

- Use of the light workover rigs (ZJ-20) instead of the 3000HP heavy rigs to complete intervention and workovers on wells 628 and RP-4. This ensured lower emissions and lower environmental footprint to achieve our objectives.

- Our in-field Eco Centre or waste management centre enables recovery of base oil from contaminated drilling fluids and drilled cuttings for re-use in well intervention activities.

The KPO Well Operations team continuously works on developing internal procedures, workflows, technology improvements and innovations aimed at improving efficiency and well operations performance. The following was achieved throughout the year 2021:

- Development and implementation of a “Business Improvement Plan” to drive efficiency of well delivery with strong focus on digitalisation and performance improvement.

- Step-up in well integrity monitoring and well integrity status – preventing and reducing the possibility of well integrity related environmental emissions.

- New technologies like local expander (ability to repair the well locally, thereby avoiding the need to re-drill) and tracer technology – driving efficient production.

TURNAROUND

The KPO Shutdown strategy is focused on optimisation of production and minimisation of cost by extending intervals between shutdowns and reduction of actual shutdown durations whilst ensuring safe continuous operations and regulatory compliance.

The strategies for the turnarounds in 2021 were affected by the impact of the COVID-19 pandemic, having resulted in transfer of scope to 2021. The major drivers for the turnarounds in 2021 were integrity and reliability. In addition to routine inspections and statutory maintenance, the main scope covered the replacement of nine vessels at Unit 3, and upgrading the centrifugal flash gas compressor. This upgrade resulted in the reciprocating compressors being removed from service as part of long-term Unit-3 Risk Reduction programme.

Unit-3 had train-by-train turnarounds in June – August 2021: scope covering routine Production and Maintenance scope and minor modifications. This resulted in a major reduction in complexity and concurrent operations risks for the total Unit 3 turnaround in September and October 2021.

In September-October 2021, KPC held a Train D turnaround aligned with Unit-3 outage focussing on replacement of the disulphide separator turret, oxidiser repairs and the upgrading of the top trays in the splitter column, compressor re-bundling apart from regular P&M scopes.

In September 2021, Unit 2 executed routine dry gas seal replacements on re-injection compressors A and B, as well as statutory maintenance, whereas they replaced dry gas seal for compressor C in April short pit-stop. The remote manifold station RMS H jump-over project in Gathering and valve replacements in KOTS were also executed in September 2021.

In addition to the regular HSE control activities and to the standard COVID-19 regulations, HSE Turnaround Plan was created by the KPO Operations HSE department identifying key areas of improvements from the previous turnarounds.

KPO’s attention on mitigating the risks of a COVID-19 outbreak focused on encouraging contractor and KPO staff to be fully vaccinated prior to the turnarounds. Contractors were reporting their vaccination percentages weekly for the two-month period leading up to the turnaround. KPO managed and motivated staff to be vaccinated as part of an ongoing company-wide initiative. Staff who had not been vaccinated were required to have weekly PCR tests throughout the turnaround execution. In addition to the vaccination effort, the statutory protocols and KPO rules were fully applied throughout the turnaround period. Due to strict application of these rules, there were no COVID-19 outbreaks or influence.

Additional risk assessments were held for two main issues at Unit 3. The first sessions related to identifying and mitigating the risks associated with the execution of train-by-train turnarounds in the summer. Also, a workshop was held to assess and mitigate risks associated with the full turnaround including risks associated with the large number of staff on-site while the 190 area of Unit 3 and nearby mini-refinery (MTU) still being in production, and the restart of Unit 3 whilst Train 4 and the condensate/flash gas systems were still in turnaround execution mode.

KPO continued to focus on safe lifting operation including awareness sessions for lifting teams, review of non-routine lifting plan by specialist and focussing on rigger and banksman roles. In addition, management and HSE team agreed that heavy lifting operations would be executed during daylight hours only.

A total of just over 495,527 man-hours were registered during the turnaround: these were completed with zero reportable cases. Overall, the planned scope of the turnaround was delivered ahead of schedule.

FIELD DEVELOPMENT PROJECTS

As the Contractor to the Republic of Qazaqstan, KPO has an obligation to conduct all operations necessary to carry out the development and production of petroleum in the contract area in accordance with International Good Oil Field Practice1.

Following the completion of the Karachaganak Phase II Initial Programme in 2003, KPO has been funding and implementing the Phase II Maintenance Programme (Phase II M). This phase includes the further activities, such as drilling of new development wells, undertaking workovers on existing wells, upgrading production facilities and other projects required to maintain a high production level for the benefit of the Republic of Qazaqstan.

From 2014, in order to avoid the increasing gas-oil-ratio causing the existing facilities to become gas constrained, KPO has been working on a programme of production Plateau Extension Projects (PEP) comprised of:

- KPC Gas De-bottlenecking project aimed at increasing the overall KPC gas processing by expanding the gas handling capacity;

- 4th Gas Reinjection Compressor project aiming to increase the annual daily average volume of gas re-injected into the reservoir and improve reservoir pressure support;

- 5th Trunkline and Gas reinjection wells project upgrading the injection network capacity downstream of Unit 2 through installation of a new trunk line, and drilling and completion of new gas injection wells.

PEP projects portfolio was maturing and developing over the years, resulting in start-up of the 5th Trunkline and Gas reinjection wells project in December 2019 with first of the three injection wells.

In 2021, the COVID-19 pandemic impact has been continuing as well, still causing some accumulated delays, including procurement delays, Force Majeure declared by some vendors, limitations imposed on travelling for the projects execution team, limited presence on site, foci of pandemic among the personnel, and many others. However, the project teams learned to progress and deliver in the emerging and challenging reality with the help of vaccination campaigns, etc.

In March 2021, KPC Gas Debottlenecking project has been successfully completed and the plant has been brought in production. Final project handover to Operations was achieved in December 2021.

The 4th Gas Reinjection Compressor project has been successfully completed and the plant was brought in production in May 2022. Final project handover to Operations is planned for June 2022.

Karachaganak Expansion Project

KPO continues development of the Karachaganak field via the Karachaganak Expansion Project Phase 1 (KEP1), scheduled in a phased manner. The KEP1 project will create additional value for the Karachaganak Parent Companies and the Republic of Qazaqstan by maintaining the stabilised liquid plateau through the provision of additional wells, process facilities and gas reinjection to manage the increasing gas oil ratio (GOR) of the field.

In December 2020, the Karachaganak Parent Companies signed the agreement sanctioning the KEP1A Project. That was another major achievement representing a new milestone in the continued development of the Karachaganak Field, building further on the achievements of Karachaganak Gas Debottlenecking Project (KGDBN) and the Fourth Injection Compressor (4IC) Project. One of the KPO’s key priorities in execution of KEP1A is maximizing the Local Content aimed at growing the local contractors’ competitiveness. The project will also create job opportunities for Qazaqstani workers.

The KEP1A Project represents the first phase of the KEP1 scope and comprises of the 5th Injection Compressor and associated facilities. The KEP1A Project pursues the opportunity to utilise the available dehydration capacity installed by KGDBN in the Karachaganak Processing Complex to increase gas re-injection capacity and integrate its scope within existing systems, utilities and facilities. The integration philosophy creates synergies and reduces CAPEX exposure. In 2021, early works have been completed ahead of plan, temporary construction facilities were also completed, compressor manufacturing commenced together with long lead items’ procurement. In 2022 to date, engineering and procurement are progressing as planned, contractor has mobilised to site and the compressor string test was successfully completed.

The KEP1B Project represents the second phase of the KEP1 scope and comprises of the 6th Injection Compressor and associated facilities. Similarly to the KEP1A, the project has the objective of increasing the liquid recovery by maximization of the production capacities of the existing facilities. The scope of project is also similar to that of KEP1A but also includes additional dehydration capacity to be installed at KPC. In 2021, the team started value assurance activities for KEP1B to be continued in 2022 leading to final investment decision.

The 6th Trunkline and 3 Injection Wells Project, which was decoupled from the KEP1A programme in March 2020 as a result of a Subsurface Technical Review, has the objective to maximise liquid recovery by increasing the field injection area. The project will re-distribute injection gas into South West Frank area of the field for pressure support of nearby low Gas-Oil-Ratio wells and better reservoir management.

In 2021, detailed design has been completed. Critical Long Lead Items, such as the 12-inch and 8-inch line pipes have been delivered; procurement of other equipment and materials has been initiated and proceeding with a good progress. Early civil construction works and double jointing of 12-inch line pipes have been completed and pipe-laying works commenced in Q2 2022.

One of the KPO’s key priorities in execution of KEP1A is maximizing the Local Content aimed at growing the local contractors’ competitiveness.

DIGITAL TRANSFORMATION PROGRAMME

The whole world is going digital and KPO cannot stay apart if we want to keep this business attractive both for the сountry and for investors. Some of the pilot projects implemented in KPO have already demonstrated a real business impact, such as reducing the personnel exposure, more effective business processes, cost efficiency and many more.

Driven by the Digital Kazakhstan programme introduced in 2017 by the RoK Government, KPO has launched its Digital Roadmap for 2018–2021. The roadmap is aimed in making the organisation safer, more effective and the more agile place. Eleven focus areas were introduced, which cover digitalization opportunities from production optimisation to process efficiency.

For example, the Telemetry Phase I project as part of the Production Optimization focus area was successfully executed in 2021, which allows acquiring real-time data from wells thus helping to significantly reduce the personnel exposure to well sites and better tune the Integrated Network Model for production optimisation purposes.

Also, some smaller projects like, Digital Signature or Launching the drones for remote inspection, being part of the Streamlining Document management focus area, were completed and have already demonstrated their benefits in daily activities.

Warehouse Management including implementation of a barcoding system was also completed, having increased the efficiency in warehouse management and stock reduction.

One of the significant digital projects in the Company is e-Procurement aimed in creation of more efficient platform with transparent process and direct sharing of data with parties involved in the authorization process. This project is ongoing and will continue in 2022.

Advanced virtual reality room with the technology for training and engineering design will allow KPO personnel to visualize information – static and dynamic data, models, simulations and interact exploiting immersive, collaborative and Virtual Reality-based solutions.

Starting from December 2020, seven E-medical examination units were installed in KPO and at present the systems are fully functional.

Besides, in collaboration with the KAZENERGY Association, KPO annually supports the Student Digital Fest (SDF) contest having engaged students of major universities in Qazaqstan. The SDF-2021 contest final stage was successfully completed in October 2021.

Since the current Digital Roadmap is scheduled for completion in 2022, KPO is planning to develop a new Digitalization and Continuous Improvement Strategy to be aligned and adopted to the new reality and external trends.

Current Pre-Strategy view is that the New 2022–2025 Roadmap will consist of five buckets around Digital Oil Field, Asset, Processes, HSSE and Enablers. Some of the projects from the new Roadmap have already been started.