Water use and disposal

Protection and rational use of water resources is a priority task faced both by the humanity and our Company. Water is the source of life and a valuable industrial raw material.

The results of our work to minimize the risks of the Company’s production impact on the use of water resources are presented below.

|

Our 2021 targets |

Target achievement |

Actions taken in 2021 |

Targets for 2022 |

|

Complete exploration activities under the Project for geological exploration works on the follow-up exploration of the site at the Industrial Wastewater Polygon №2 |

Completed |

All pre-exploration geological and hydrogeological works were carried out at the site of Polygon №2, which allowed proving the reservoir capacity to accept increased volumes of industrial waste water. Main long-term solutions for injecting wastewater were presented to the Authorised body on environmental protection to which a conclusion requiring an environmental impact assessment was issued. |

Carry out development of Annex №3 to the industrial waste water injection project.

|

Why is it important to us?

Excessive and irrational water consumption may lead to impacts associated with the depletion of water resources and water shortage for industrial and economic needs, deterioration of aquatic ecosystems and water bodies becoming increasingly incapable of natural reproduction and purification.

The Company’s target is to use water resources rationally in order to preserve them. KPO controls the use of clean water within the Company by undertaking a set of measures for conservation of water resources and maximum re-use of treated water, wherever possible.

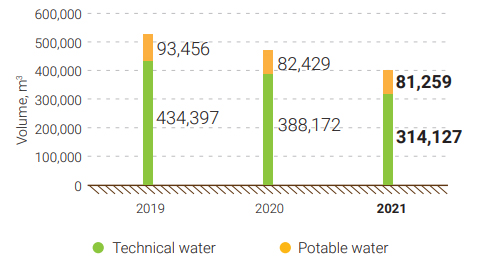

In 2021, the total KPO water consumption was 395,386 m3, of which technical water made up 314,127 m3, and potable water – 81,259 m3.

Graph 23. KPO water consumption, 2019 – 2021

In 2021, the volume of water used by KPO for production needs was 16 % lower than in 2020. The domestic needs’ water consumption was lower too versus 2020. The reduction of water consumption was related to the drilling scope cut, better control over water losses during transportation, measures to optimize water consumption due to a decrease in the water level in holding pond № 1 at the Konchubai Gully, secondary use for technical needs of treated wastewater from storage ponds, rainwater and meltwater from lagoons and groundwater from wells.

The main source of water supply for production needs in the Karachaganak field is the holding pond № 1 at the Konchubai Gully, while for household and domestic needs it is the Zharsuat water intake. The source of water supply for household, domestic and production needs of the Bolshoi Chagan OPS is the Serebryakovskiy water intake, while for the Atyrau Terminal is the Kigach water intake.

Konchubai Gully is not part of the list of fishery waters based on the WQO Administration Resolution dated 22.12.2014 (№ 325). The Konchubai Gully is not fed by groundwater; it collects water only during springtime by snow melting and rainfalls.

According to the Special Water Use Permit valid until 24.05.2025 for water intake from the Konchubai Gully for industrial needs, the KPO annual intake limit constitutes 741,432 м3. The Permit is issued by the RSE ‘Zhaiyk-Caspian Basin Inspectorate for Water Resources Management and Conservation of Water Resources Committee of the RoQ Ministry of Environmental Protection, Geology & Natural Resources’. The holding pond № 1 at the Konchubai Gully is operated in line with the Operating Rules for ensuring optimum water use conditions, integrity of structures, environmental protection, and also as per the Process operating procedure for safe operation and maintenance of the holding pond’s hydraulic structures.

In 2021, the combination of prolonged dry periods and little snow floods observed in the region has led to a critical decrease in the water level in holding pond № 1. In this regard, during 2021, KPO carried out a number of activities allowing optimization of technical water consumption and reuse of treated wastewater, rainwater, and melt water. Additionally, after conducting experimental filtration studies at wells, groundwater from wells was sent to operational facilities for reusing for technical needs. The Company has started and continues its research and development of framework of water consumption from alternative sources.

Water intake from other sources is ensured through contracts with water suppliers.

In 2021, the potable water was used for domestic needs of the KPO facilities. By exception, at the Bolshoi Chagan Oil Pumping Station (OPS) the potable water has been supplied by the RSE ‘KazVodKhoz’ WQO Branch, due to absence of alternative sources of water supply, has been used to fill the fire water tanks for fire safety purposes.

Table 38 shows KPO water consumption breakdown by source.

Tab. 38. KPO water consumption in 2019 – 2021 broken down by source, m3

|

№ |

Source |

Facility |

Water quality |

2021 |

2020 |

2019 |

|

1 |

Zharsuat water intake facility (domestic needs) |

KOGCF |

groundwater, potable |

79,852 |

80,957 |

91,851 |

|

2 |

Serebryakovskiy water intake facility |

Bolshoi Chagan OPS |

groundwater, potable |

1,407 |

1,472 |

1,605 |

|

|

Domestic needs |

|

|

868 |

938 |

924 |

|

|

Production needs |

|

|

539 |

534 |

681 |

|

3 |

Konchubai Gully water intake facility (production needs) |

KOGCF |

surface water, technical |

310,352 |

384,453 |

431,616 |

|

4 |

Kigach water intake facility |

Atyrau Terminal |

surface water, technical |

3,775 |

3,719 |

2,781 |

|

|

Domestic needs |

|

|

808 |

759 |

777 |

|

|

Production needs |

|

|

2,967 |

2,960 |

2,004 |

Discharge of treated wastewater

KPO uses special man-made facilities for collecting treated domestic and industrial wastewater and storm runoffs. These facilities exclude a possibility of contaminants soaking into the soil and groundwater and allow collecting the treated wastewater for their re-use for technical needs, thereby reducing the fresh water intake. The types of wastewater collection facilities were shown in the 2018 Sustainability Report (Tab. 40, p. 105).

Formation water produced with hydrocarbons and process wastewater are treated and injected into the deep-lying formations of the Karachaganak Field Subsurface Wastewater Disposal Polygons № 1 and № 2. Wastewater injection is the international practice of disposing wastewater that allows preventing the formation of salt-containing waste on the surface during the treatment. Owing to the reliable water shutoff and soil properties, which are perfect for the injection of wastewater, the migration of wastewater into upper aquifers is ruled out.

According to the RoQ legislation, the volume of discharged wastewater and amount of discharged contaminants are estimated and justified in the Company project documentation and regulated by special permits. Wastewater generated as a result of the KPO economic and operational activities is not discharged into the natural water bodies.

Table 39 shows the KPO discharge volumes in 2019–2021 by wastewater types and receiving facilities.

Comparing to 2020, the volume of wastewater discharged by Company in 2021 increased by 12.38 %. Of that, in 2021 compared to 2020, the volume of injected industrial wastewater increased by 12.35 %. The increase in industrial wastewater was due to increase of produced water. The types of treated wastewater and contaminants were presented in the 2017 Sustainability Report (p. 93).

In 2021, the discharge of contaminants amounted to 58,981 tonnes (which was 28.2 % more compared to 2020 – 46,006 tonnes). Of them, 58,166 tonnes were discharged within the maximum permissible discharge (MPD) limits, while the excess discharge amounted to 815 tonnes.

Excessive discharge of contaminants was due to insignificant exceedance of the MPD limits in terms of hydrogen sulphide, chlorides and methanol content in wastewater injected into Subsurface Waste Water Disposal Polygons № 1 and № 2. Excessive discharge of contaminants with domestic wastewater to the holding ponds was not observed, except for a slight excess in ammonium nitrogen, chlorides, and phosphates. As provided by the RoQ Tax Legislation, the Company effected necessary payments for the discharges of contaminants.

Overall, wastewater injection has no effect on the environmental components such as soil, flora and fauna, as wastewater is injected into effectively isolated deep horizons with high-mineralized groundwater that is not used for domestic and potable, balneological, and process needs, irrigation or livestock farming.

Tab. 39. Total discharge volume and contaminants by wastewater type and receiving facility, 2019–2021, m3

|

Receiving facility |

Type of wastewater |

2021 |

2020 |

2019 |

|||

|

Discharge volumes, m3 |

Amount of contaminants, tonnes |

Discharge volumes, m3 |

Amount of contaminants, tonnes |

Discharge volumes, m3 |

Amount of contaminants, tonnes |

||

|

Holding ponds |

Treated domestic wastewater |

72,123 |

44.51 |

64,244 |

34.38 |

68,763 |

35.72 |

|

Subsurface Waste Water Disposal Polygons |

Industrial wastewater, process and produced wastewater |

780,755 |

58,935 |

694,893 |

45,970 |

628,819 |

39,645 |

|

Terrain of Bolshoi Chagan OPS and Atyrau Terminal OPS |

Rainfall and snow melt wastewater |

2,538 |

1,595 |

1,982 |

1.56 |

3,546 |

2.05 |

|

Total discharge |

855,415 |

58,981 |

761,119 |

46,006 |

701,128 |

39,683 |

|

Reuse of treated and other wastewater

In order to reduce fresh water intake for such works and operations like drilling, drilling muds preparation, watering of planted trees, dust suppression on roads and constructed sites KPO uses treated domestic, production storm wastewater and storm runoffs. The wastewater is re-used at the Company facilities in line with the 2018–2022 Operating Procedure.

In 2021, treated waste water, rainfall and melted water, as well as groundwater from wells were also used for the technical needs of production facilities.

The volume of wastewater reused for technical needs by KPO in 2021 made up 11.3 % of the technical water consumed from the Konchubai Gully. In 2021, the Company reused 35,061 m3 of treated wastewater for technical needs, mostly for dust suppression. Table 40 shows the activities that utilize treated wastewater and water.

Tab. 40. Reuse of treated wastewater and groundwater in 2019 – 2021, m3

|

|

2021 |

2020 |

2019 |

|

The total volume of re-used treated wastewater, including: |

35,061 |

18,313 |

38,545 |

|

Drilling operations and drilling mud preparation |

5,317 |

3,482 |

30,117 |

|

Irrigation, hydro tests, and replenishing of fire tanks |

8,465 |

335 |

1,088 |

|

Dust suppression |

17,917 |

14,496 |

7,340 |

|

Technical needs of production facilities |

3,362 |

|

|

INDUSTRIAL WASTEWATER MANAGEMENT

Managing the produced and industrial effluent water is one of the main challenges faced by KPO in the Karachaganak Field.

KPO’s wastewater management strategy consists of implementation of a portfolio of interconnected projects aimed at removal of production restrictions in terms of produced water handling as well as ensuring personnel safety, asset integrity and environmental compliance.

The Company took a decision to update the Project for wastewater injection into Polygons in order to increase the scope of injected water in Polygon 2 up to 1,100 thous.m3 from 2023 to 2037. The Project’s Amendment No.3 will contain the planned increase of wastewater injection and activities targeting to expand the potential of injecting wells. Upon completion, development of the environmental impact assessment to Amendment No.3 followed by public hearings are scheduled.

In 2021, two planned projects were completed: workover of the second absorbing well for more effective utilization of wastewater and commission of a modified gas sweetening unit in order to automate a causterization process.

In 2022, refinement and implementation activities will continue including the upgrade of a caustic neutralisation unit. Also, it is expected that the 2022 turnaround will cover a replacement of induced gas flotation vessels and a tilted plate separator required for treating process effluents from oil. The vessels’ replacement will ensure asset integrity and higher capacity of facilities and consequently provide better oil and water separation, which will positively affect the operation of the entire wastewater treatment system before disposal into deep horizons.

Tab. 41. Implemented industrial wastewater management projects in 2021

|

Project |

Business driver |

Note |

|

Start-up of a modified gasoline demercaptanization unit |

Safe operations |

Implementation of the project allowed optimizing generation of the spent caustic soda, which further goes to a neutralization unit. By means of process automation the risks for personnel exposure to toxic agents. |

|

Workover of the two water injection wells |

Production maintenance |

Workover of the two absorbing wells with application of proppant fracturing has led to a significant raise of wells acceptability of wastewater re-injection for increasing production. |