If handled unsafely, a hazardous production waste, its storage and disposal sites, may pose a threat to the environment and cause pollution of air, underground and surface waters, soils and vegetation, which may have a negative impact on the environment and the health of people.

KPO carries out complex work to prevent negative impact on the environment, i.e. carries out burial and accumulation only in the arranged waste storage sites, monitors the prevention of excess burial and accumulation of waste, as well as the timely removal of waste from accumulation sites.

Waste management

Waste handling in KPO focuses on reducing real and potential hazards that production waste, generated by the Company, may pose to people and the environment.

Our target is to treat and recycle waste at our facilities, cut down waste transfer to landfills, reduce negative impact from burials, as well as to research and apply new methods and technologies.

As per the working monitoring program, KPO performs regular production environmental control (PEC) over the environmental conditions at the waste burial and accumulation sites in the field. In 2022, the monitoring did not reveal direct negative effects on the environmental components. Within the framework of the PEC, quantitative control is exercised over the movement of wastes in order to account for the burial volumes, as well as the volumes and time of waste accumulation.

The results of our work to minimize the risks of the Company’s production waste impact on the environment are presented below in the table and further in the text.

Tab. 41. Targets in waste management

|

Our 2022 targets |

Target achievement |

Actions taken in 2022 |

Targets for 2023 |

|

Ensure implementation of activities scheduled for 2022 as per KOGCF Waste Management Program, and as per Bolshoi Chagan Ops and Atyrau OPS Waste Management Programmes. |

Completed |

All activities scheduled for 2022 as per the Waste Management Programme were implemented throughout the year. |

Ensure implementation of activities scheduled for 2023 as per KOGCF Waste Management Programme, and as per Bolshoi Chagan Ops and Atyrau OPS Waste Management Programmes. |

KPO processes related to production, processing and transportation of raw materials, as well as the use of special equipment, materials and other required resources, inevitably involve generation of waste.

Measures taken by KPO to reduce the volume of generated waste, to ensure compliance with environmental safety rules during the accumulation, collection and transportation, segregation, reuse, recycling, treatment and reduction of waste, including reducing their hazardous properties, as well as environmentally friendly burial – all this enables to significantly mitigate the adverse impact on people and the environment.

The KPO Waste Management Program for 2022 provides indicators and measures to gradually reduce the accumulated and generated waste volumes and level of hazardous properties. The Company applies the following waste management methods:

- waste recovery to process stream;

- waste treatment at the Eco Centre facilities;

- waste burial at the Eco Centre facilities;

- waste handover to specialist contractor organizations for further processing, reuse or destruction.

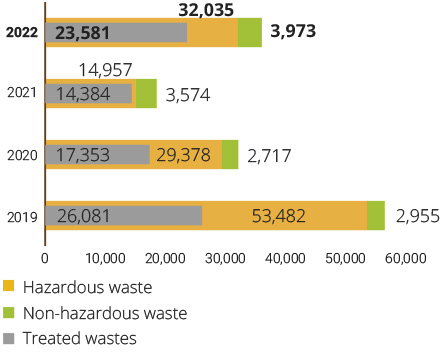

In 2022, the total amount of waste generated at KPO facilities was 37,243 tonnes. Compared to 2021, the amount of KPO waste in 2022 increased by 17,583 tons, which is mainly due to an increase in well operations, turnaround activities at KOGCF main facilities, construction of new facilities, as well as the inclusion of waste generated by contractor activities in KOGCF. Graph 25 shows all types of waste generated in KPO.

According to the Unified republican form of the waste information reporting system, the total volume of waste generated in 2022 included both wastes generated and treated.

Graph 25. Waste generated at KPO facilities in 2019–2022, tonnes

Waste processing and burial

The Company production and consumption wastes are treated at the Eco Centre facilities or the waste management complex. The facility ensures cost-efficient and environmentally safe recycling and treatment of solid waste and fluids and is considered to be an example of the best drilling waste management practice in the West Qazaqstan Oblast.

Drilling wastes are treated by means of technologies, which allow not only reducing their volume and hazard, but also recovering valuable components from them, and treating the waste for further reuse.

Waste recycling back into production process exercised by the Company is the best possible way to re-use the generated waste.

The KPO Eco Centre comprises five waste treatment facilities, as well as a Landfill for its safe disposal.

All Waste Management Programme (WMP) measures scheduled for 2022, including waste segregation, reuse, processing and reduction of their quantities and hazardous properties, were implemented throughout the year. During 2022 the following activities were completed:

Tab. 42. Eco Centre facilities and recycling activities in 2022

|

Eco-Centre Units |

Waste treatment activities in 2022 |

|

Thermo-mechanical cutting cleaning facility (TCC) |

Owing to recovery technology of base oil and water from the treated oil-based drill cuttings, in 2022 the quantity of KPO buried waste was reduced by 17 %. |

|

In 2022, 9,008 tonnes of waste were treated; 1,506 tonnes of base oil and water were separated; and 7,502 tonnes of waste treated at the TCC were buried at the Solid Industrial Waste Landfill. |

|

|

General Purpose Incinerator (GPI) |

Resulting from waste incineration in the GPI, quantity of buried waste was reduced by 89 %. In 2022, 600 tonnes of waste were sent for incineration, following which 69 tonnes of ash were buried at the Eco-Centre Solid industrial waste landfill. |

|

Liquid treatment plant (LTP) |

In 2022, 8,674 tonnes of liquid waste were treated. The process resulted in 5,153 tonnes of treated brines and muds, which were sent for re-use – preparation of drilling brines and muds. |

|

Waste Segregation Unit (WSU) |

In 2022, out of 834 tonnes of solid domestic waste, 600 tonnes were sent to General Purpose Incinerator for incineration, 123 tonnes, including waste paper, metal scrap, glass and plastic were sorted for handing over to the specialist organizations for treatment and reuse. 111 tonnes of solid domestic waste handed over to specialist organizations for burial at the SDW Landfills. 252 tonnes of food waste handed over to specialist organization for processing. |

|

Solid Industrial Waste Landfill |

At the end of 2022, 16 cells of the Solid industrial Waste Landfill were capped and closed. |

In 2022, the Company continued to excavate wastes from the old Solid Waste and Spent Drilling Fluids Storage Site for further treatment at the Thermo-mechanical cutting cleaning facility and burial at the Solid Industrial Waste Landfill. The waste is disposed at the Landfill in compliance with the RoQ environmental legislation.

In 2022, 5,318 tonnes (as compared to 4,308 tonnes in 2021) were sent for treatment from the Solid waste and Spent Drilling Liquids Storage Site. Increase of treatment amount was due to Rotary Kiln Incinerator back in service after the repairs. Processing of waste from the old site is planned to continue in 2023.

Table 43 shows the waste handling methods used by the Company in 2022.

Tab. 43. KPO’s waste handling methods in 2022, tonnes

|

No. |

Waste handling method |

Generated hazardous waste |

Generated non-hazardous waste |

Municipal waste |

TOTAL |

|

1 |

Waste balance at the enterprise at the beginning of 2022 |

337,711 |

530 |

1 |

338,242 |

|

2 |

Generated during the reporting year |

32,035 |

3,973 |

1,235 |

37,243 |

|

3 |

Reused at the enterprise |

5,843 |

0 |

0 |

5,843 |

|

4 |

Treated at the enterprise facilities |

23,354 |

226 |

722 |

24,302 |

|

5 |

Incineration in General Purpose Incinerator (without power generation) |

0.5 |

0 |

600 |

600.5 |

|

6 |

Burial at Solid Industrial Waste Landfill |

14,424 |

0 |

0 |

14,424 |

|

7 |

Temporary storage of drilling liquid wastes in Checks #35 A/B Eco Centre |

3,718 |

0 |

0 |

3,718 |

|

8 |

Handed over to specialised contractors |

1,468 |

3,747 |

624 |

5,839 |

|

9 |

Waste balance at the enterprise at the end of 2022 |

350,262 |

8 |

4 |

350,274 |

Note: the amount of waste is defined by weighing of each batch of waste at the Eco Centre weight scales prior to its transportation for treatment, segregation, removal, burial or other operations. Waste quantities are logged in the load supporting documents (control tickets, waste handover certificates) and further in the Company’s waste accounting database.

The KPO waste is mainly produced during well drilling and workover activities. Besides, depend on the type of the drilling mud used the water or oil-based drill cuttings are generated. The solid and liquid drilling waste generated in 2022 amounted to 17,552 tonnes (68 % of the initially generated waste, i.e. waste volume before treatment). Drilling wastes were significantly increased due to increase of well operations.

Table No. 44 shows the main types of drilling waste broken down by handling methods. As table shows, only water-based mud and brines are subject to disposal at the Eco Centre's cells 35 A/B, and the water-based drill cuttings to be buried at the Landfill. Oil-based drilling cuttings are subject to burying after pre-treatment and extraction of the oil base.

Tab. 44. Waste generated from well operations by handling methods, 2020 – 2022

|

No. |

Type of waste |

Generated waste, tonnes |

Handling methods |

||

|

2022 |

2021 |

2020 |

|||

|

1 |

Spent water-based drilling mud |

1,154 |

382 |

4,125 |

Treatment at Liquid treatment plant (LTP) |

|

3,467 |

383 |

1,020 |

Temporary storage of drilling liquid wastes (Checks #35 A/B Eco Centre) |

||

|

2 |

Water-based drilling cuttings |

2,716 |

987 |

533 |

Burial |

|

0 |

0 |

0 |

Heat treatment in the Rotary Kiln Incinerator (RKI) |

||

|

3 |

Spent oil-based drilling mud |

1,257 |

432 |

818 |

Treatment at the Thermo-mechanical cutting cleaning facility (TCC) and Liquid treatment plant (LTP), heat treatment in the Rotary Kiln Incinerator (RKI) |

|

4 |

Oil-based drilling cuttings |

5,760 |

2,776 |

5,316 |

Treated at the TCC with extraction of oil base, water and followed by the burial of the solid part, heat treatment in Rotary-Kiln Incinerator |

|

5 |

Spent brines |

3022 |

1,438 |

1,932 |

Treatment at TCC & LTP, heat treatment in Rotary-Kiln Incinerator |

|

155 |

189 |

296 |

Temporary storage of drilling liquid wastes (Checks #35 A/B Eco Centre) |

||

|

6 |

Oil cuttings |

21 |

60 |

11 |

Heat treatment in the Rotary Kiln Incinerator, treatment at TCC |

Within the contract terms, the Company hands over part of the waste for recycling to specialist contractors, who make their own decision on further waste handling methods once the waste has been accepted from KPO, and report on its transfer to third parties on a quarterly basis. Depending on the type, specialised enterprises hand over the waste for treatment with subsequent production of consumer goods, demercurization, regeneration, thermal treatment, incineration, physical and chemical treatment, dismantling into component parts with further transfer to concerned enterprises as recyclables.

Based on Article 351 of the RoQ Environmental Code that prohibits burial of waste plastic, plastic, polyethylene and polyethylene terephthalate packaging, waste paper, cardboard, paper waste, glass cullet at the Landfills, the Company carries out sorting and segregation of such waste with the involvement of contractors that lease office buildings to the Company. These types of waste are then handed over to specialized enterprises to be used as recyclables.

From 2011 till the end of 2022, for the whole period of the waste paper segregation, about 831 tonnes of the waste paper had been collected and handed over to local companies to produce consumer goods. The segregation of spent batteries was arranged in all Company office premises. 110 kg of batteries was collected in 2022.

Food Waste Treatment

In order to comply with the requirements of the RoQ Environmental Code, during 2021–2022 KPO has implemented the most efficient way to handle food waste generated at the food facilities of the Karachaganak field. The contract was signed for the biocomposting of food waste. In 2022, the Company handed over 252 tons of food waste from the food facilities of the Karachaganak field to the food waste processing enterprise. The resulting biocompost is used in agriculture and forestry as organic fertilizers to restore and improve soil fertility.