Sustainability

- Home

- /

- Sustainability

- /

- Transition to carbon neutrality

Transition to carbon neutrality

Addressing climate change is the biggest challenge that the world is facing today. The new Environmental Code of the Republic of Qazaqstan is aimed at stimulating the decarbonization of the country’s economy and «green» development.

In its turn, KPO works toward contributing to decarbonisation of the economy of Kazakhstan. In late 2021, KPO management has declared the launch of a Project 365 targeting to achieve a number of ambitious goals covering three areas: diversification and revenue growth, cost base management and the «green» transformation.

In September 2021, KPO held a seminar solely on green transition with engagement of its Parent Companies. As a result, a vision for the decarbonization of the Karachaganak Field was devised, which is to become one of the world’s biggest producers of hydrocarbons and energy with achieved carbon neutrality in scopes 1 and 2 by 2037. Furthermore, KPO has set a goal to develop a clear strategy of achieving carbon neutrality by end 2023 with definition of all interim steps for reducing GHG emissions.

Reduction of GHG emissions

In order to support the goal of reaching carbon neutrality (scopes 1 and 2) by 2037, the Company has initiated extensive work to study opportunities of reducing GHG emissions. In 2021, research studies were started to explore options, such as waste heat recovery, CO2 capture and storage, renewable energy supplies, participation in carbon trading, enhancement of energy efficiency, and other. The activities are ongoing with plans for expansion in 2022.

Direct greenhouse gas emissions

Direct greenhouse gas (GHG) emissions are regulated across KPO in line with the national quotas trading system. KPO has obtained quotas for the 2021 GHG emissions (CO2) in the amount of 2,369,945 tonnes on the basis of specific emissions indicators (benchmark). In 2021, actual emissions amounted to 1,727,683 тонн tonnes of CO2, which made 73 % of the quota.

Assessment of GHG emissions is performed for carbon dioxide (СО2), methane (СН4) and nitrogen oxide (N2O), using the calculation method based on the Company’s operations data (in terms of fuel consumption and laboratory data on fuel composition).

According to the verified GHG Emissions Inventory Report for 2020, the total volume of GHG emissions amounted to 1,745,768 tonnes in СО2-equivalent, of which СО2 contribution equalled to 1,727,683 tonnes of СО2-equivalent (99%), CH4 — 9,586 tonnes of СО2-equivalent (0.5%), N2O — 8 499 tonnes of СО2-equivalent (0.5%).

Information on the dynamics of generated GHG emissions is provided in table below. In 2021, minor reduction in GHG emissions (by 4%) versus 2020 is attributed to a decrease in hydrocarbon production capacity in the reporting year.

Dynamics of GHG emissions generated from KPO production activities, 2019-2021

Total volume of greenhouse gas emissions (tonnes of CO2 equivalent) | |||||

From fuel combustion at flares and incinerators | From fuel combustion at stationary sources | Fugitive emissions* | Total GHG emissions in 2021 | Total GHG emissions in 2020 | Total GHG emissions in 2019 |

1,602,469 | 136,211 | 7,088 | 1,745,768 | 1,821,604 | 1,870,324 |

* Considering the use of internal calculation methodology for fugitive GHG emissions approved for use for the purposes of inventory by the RoQ Ministry of Environment, Geology and Natural Resources. The volume of figutive GHG emissions in 2021 calculated by the methodology applied at the GHG emissions inventory for 2018-2019 made up 151,916 of CO2-equivalent.

Specific greenhouse gas emissions

In 2021, KPO specific GHG emissions amounted to 63 tonnes of СО2 per thousand tonnes of produced hydrocarbons, which is fully consistent with the target indicators of the specific GHG emissions of no more than 67 tonnes of CO2 per thousand tonnes of hydrocarbon produced.

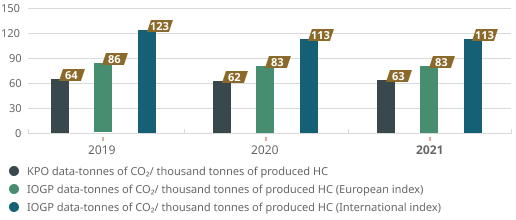

Graph below shows the dynamics of specific GHG emissions comparing to the specific emissions data provided by the IOGP. The actual specific GHG emissions at KPO are 23% lower than the European indicators and 44% lower than the international ones.

Dynamics of specific GHG emissions per unit of produced hydrocarbons (HC)*, 2019-2021

*The data was sourced by Annual reports of the International Associations of Oil and Gas Producers (IOGP) — ‘Environmental Performance Indicators — 2020 Data’. The 2020 data was used for comparison purpose, as the 2021 IOGP Report was not available at the time this issue was prepared.

Indirect GHG emissions

Indirect GHG emissions at Karachaganak Field resulting from the consumption of imported electricity in 2021 account for an insignificant part (0.06%), since the company has a gas turbine power plant, the main purpose of which is to provide its own electricity to the entire production complex of the field and nearby settlements. These emissions are not subject to accounting and are not included in the reporting under the internal system of quotas for GHG emissions of the Republic of Qazaqstan. Information on them is provided only in reports to KPO Parent companies.

For 2021 the indirect GHG emissions at KPO amounted to 1,147 tons of CO2.

Case Study

CASE STUDY: FUGITIVE GHG EMISSIONS CALCULATION METHODOLOGY DEVELOPMENT | |

Context / short description: | Based on the outcomes of the fugitive GHG Emissions Monitoring Campaign from 2015 to 2019 it was identified that the actual GHG (methane) emissions are significantly lower (by 93%) than GHG emission volumes calculated in line with the Guidelines on GHG Air Emissions Calculation for Gas Production, Transportation and Storage Facilities. Based on the provisions of the Article 94-11 of the RoQ Environmental Code and ST RQ GOST R ISO 14064-1-2010, KPO took a decision to develop its own methodology that would allow to utilize the outcomes of the monitoring and therefore minimize indeterminacy in future calculations of fugitive GHG emissions at the Karachaganak field facilities. |

Goal: | KPO’s own methodology will support the delivery of the following objectives:

|

Solution / actions: | Considering the internal developed materials and based on the provisions of the Guidelines EPA-453/R-95-017, KPO Environmental Department has done huge work to develop and implement the Fugitive GHG Emissions Calculation Methodology. For this purpose, the following materials were studied and taken into consideration:

The new methodology was approved by the Ministry of Environment, Geology and Natural Resources of the Republic of Qazaqstan for using during the GHG emissions inventory at the Karachaganak field production facilities. |

Result: |

|